ABOUT US

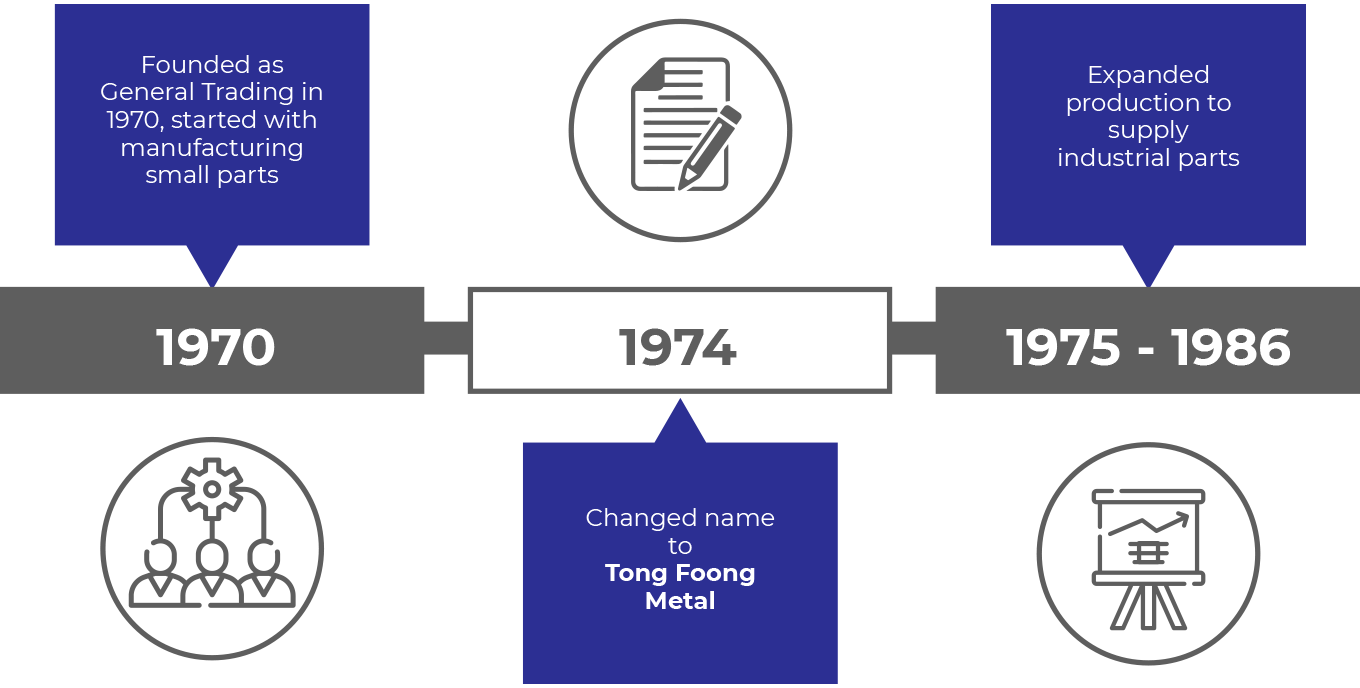

TF Metal Industries started off with the name General Trading in 1970 and focused on manufacturing of small parts such as bottle cover. Since then we had built up a reputation for our specialties in aluminium sand casting and gravity die casting.

In 1974, General Trading was renamed to Tong Foong Metal. As a new entrant in the industry, Tong Foong Metal broaden its production supply to satisfy customers from construction, agriculture and power supply industries.

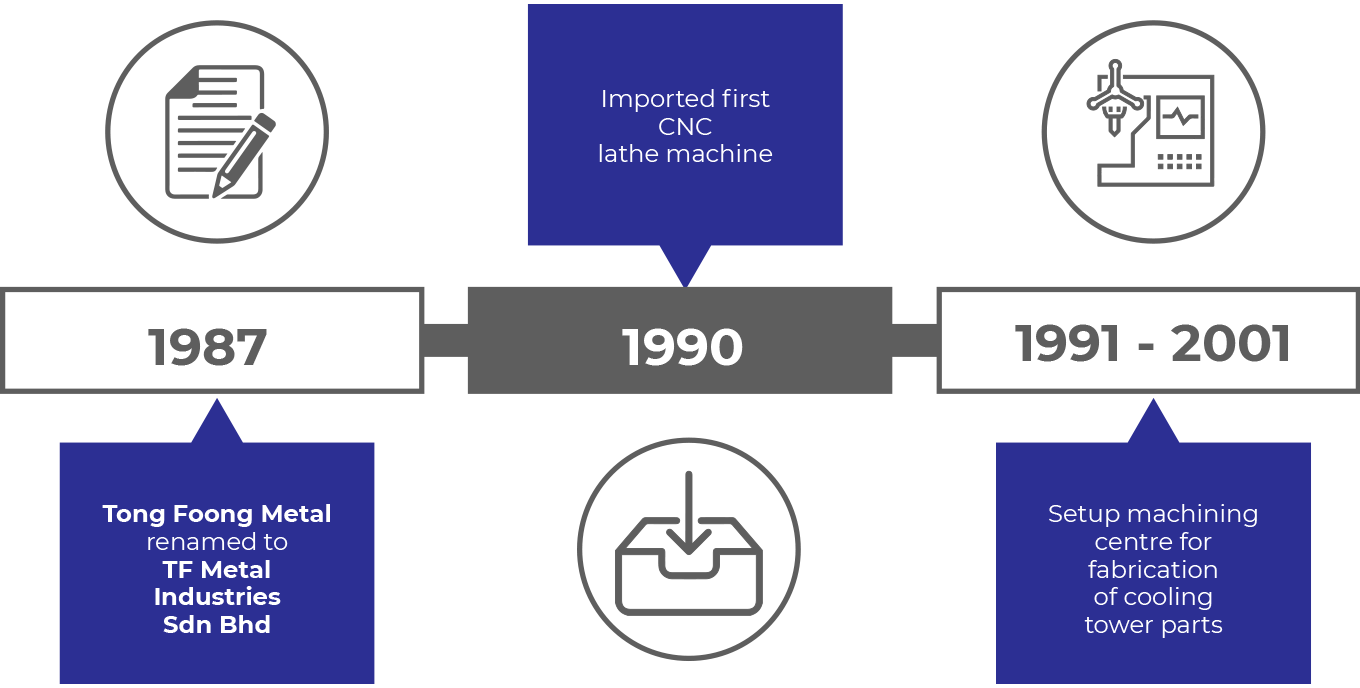

In 1987, Tong Foong Metal acquired more capital through new shareholders and had been renamed as TF Metal Industries Sdn Bhd.

TF Metal kicked off as an enterprise in the 90’s and improved the production capabilities from casting to machining service by importing the first CNC lathe machine and set up a machining centre, which focused on essential parts of cooling towers.

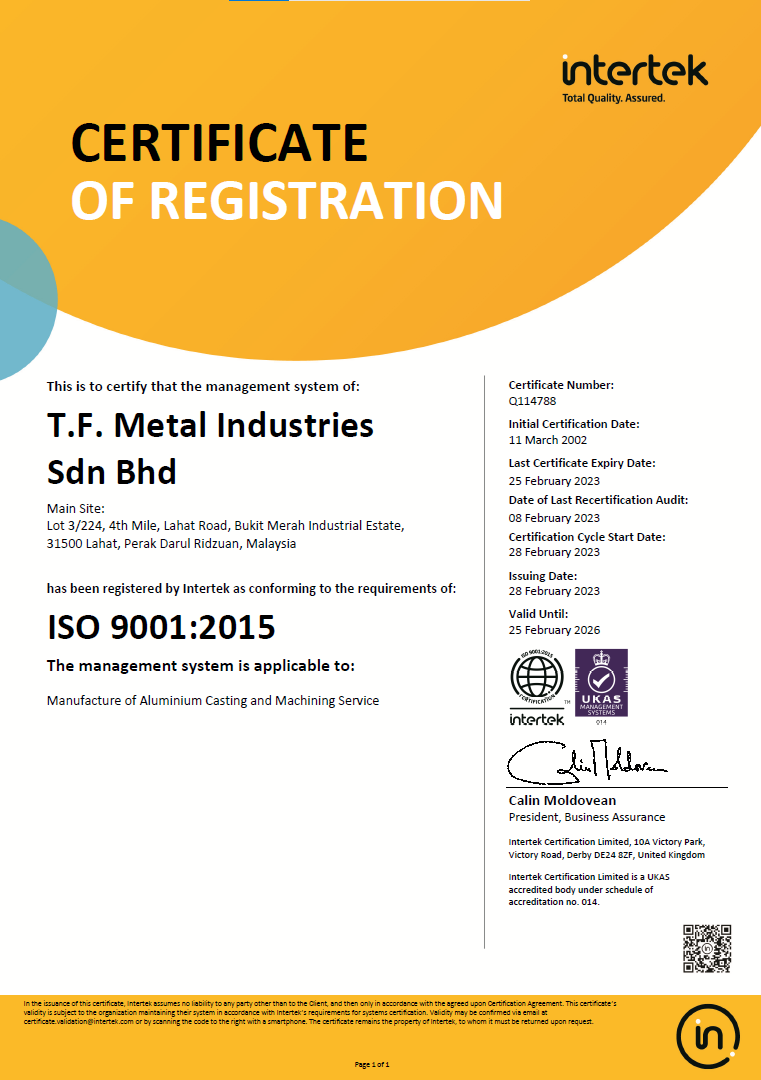

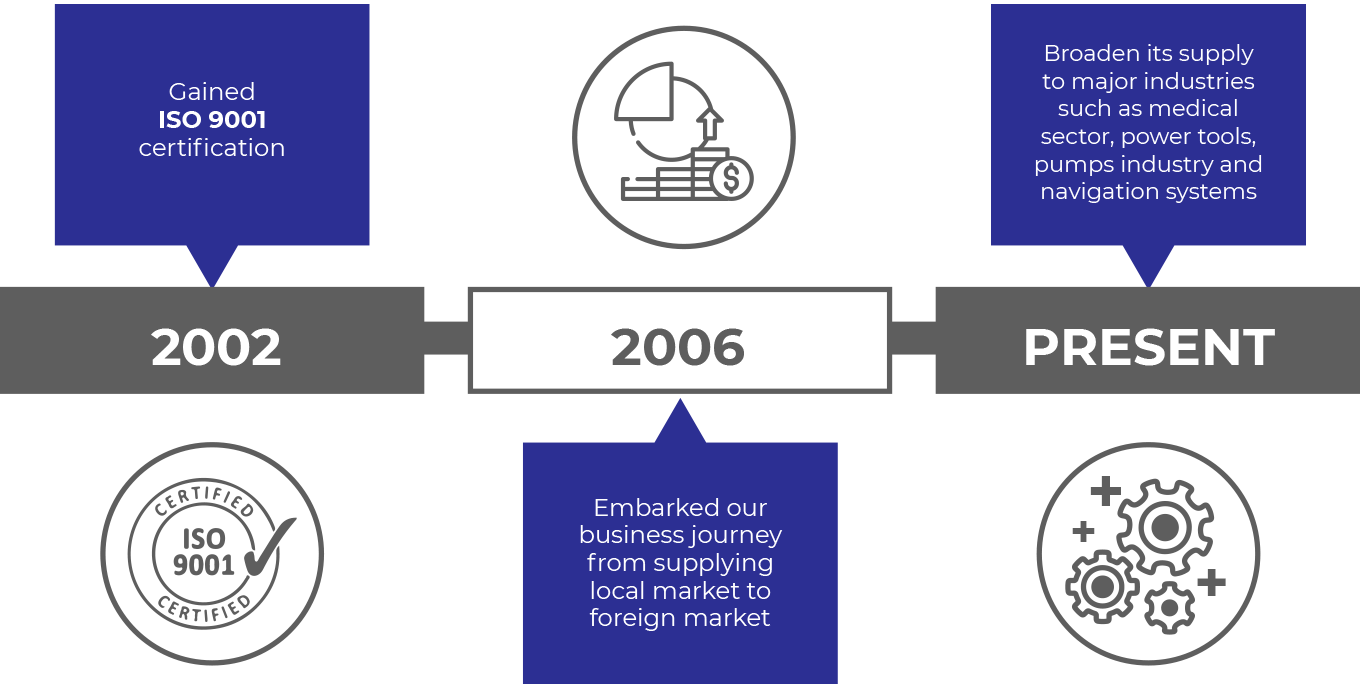

Another 12 years of continuous dedication to maintain customers’ satisfaction level in our products gained TF Metal an ISO 9001:2000 status on 16 Feb 2002. Following that, our production boosted by supplying, raw or machined castings to customers from various industries such as oil and gas, medical instruments, filtration systems and navigation systems.

TF Metal is committed to continuous improving its facilities, bring in advanced technology and strive to be one of the premier company and one-stop solution centre for aluminium sand casting and gravity die casting.

CORE BUSINESS

Gravity Die Casting

One of our core strengths is production of quality aluminium gravity die castings for a range of industries, for instance medical sector, analytical instruments, power tools industry, pumps industry and navigation systems.

Gravity die casting is a permanent mold casting process. It involves the pouring of molten metal into the mold by using a ladle. Metal fills up the cavity under the force of gravity, with no other external forces involved in the process.

CORE BUSINESS

Aluminium Sand Casting

Sand Casting is a metal casting process distinguished by using sand as the mold material. TF Metal has been fabricating small to large aluminium sand castings up to 300kg.

Compared to gravity die casting, sand casting molds can be created at lower setup cost. It is also more versatile and easier to modify. These advantages make sand casting the ideal choice for low and medium volume production.

CORE BUSINESS

CNC Machining

Apart from casting, CNC machining is also our key operation, offering customers a one-stop solution service from cast, machine and finishing. Indirectly reducing lead times and minimize logistic and management cost of dealing with several contractors.

VISION

To be a local leading company in gravity casting industry equipped with automated production.

MISSION

To provide on time delivery of quality products at the most competitive prices by striving for the continuous improvements in the facilities.

OUR MILESTONE

QUALITY & CERTIFICATES